Home

Land & Marine

Geological Services Pty Ltd

(L&MGSPL)

L&MGSPL and its Subsidiary Company TSF Reviews PL (TSFRPL) specialise in the execution of high-level geotechnical work associated with tailings storage facilities (TSFs) and other mine infrastructure from initial site reconnaissance and assessment during exploration through study phases for the development of mine projects.

Execution of high-level geotechnical work associated with tailings storage facilities (TSFs)

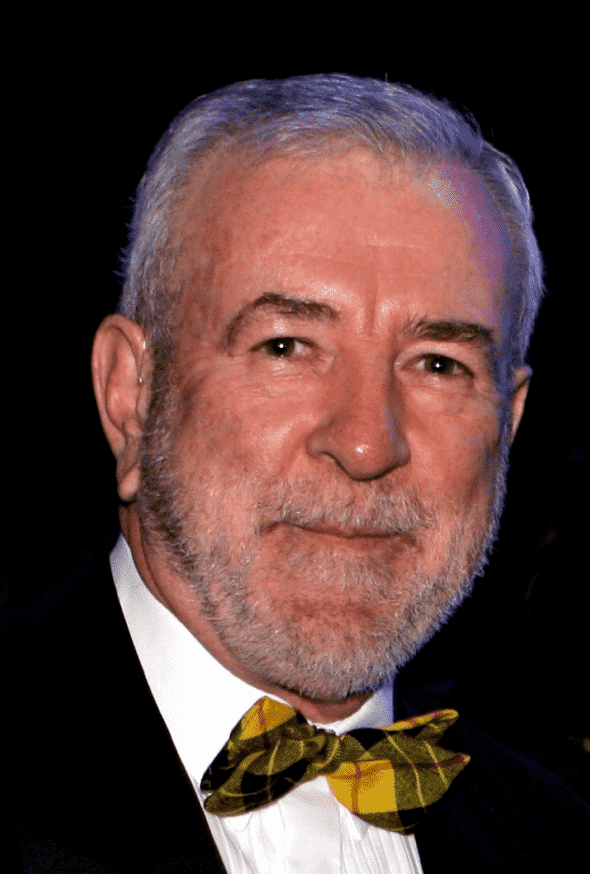

Chris Lane is Director and Principal Consultant (Engineering and Environmental Geologist) of L&MGSPL/TSFRPL with broad experience in civil construction fields, including site investigation of land based and marine based developments, and particular expertise in large resource projects.

He has more than 30 years’ experience in resource projects including site investigation and construction of infrastructure (plant sites, heap leach facilities, roads, railways and airstrips and tailing storage facilities (TSFs)).

Tailings storage facility experience

Involvement with TSFs covers aspects of design, construction, auditing and tailings/residue management reviews for a large number of projects covering a range of commodities including: alumina residue, bauxite residue, base metals (copper, lead and zinc), coal, gold, graphite, iron ore, manganese, nickel (sulphide and laterite), phosphate residues, rare earth residues, uranium and vanadium.

Special interests are dry stacked tailings storage facilities (DSTSF), Inpit TSFs, and Integrated waste landforms (IWL).

Chris has experience in the following overseas locations United Kingdom; Middle East (Egypt, Iran, Oman, Saudi Arabia and the United Arab Emirates); Armenia; Pakistan; Southeast Asia (Indonesia, Malaysia, Papua New Guinea, Philippines and Vietnam); West Africa (Burkina Faso, Ghana, Ivory Coast, Mali, Senegal), East Africa (Ethiopia, Tanzania) and Southern Africa (Mozambique, South Africa and the Democratic Republic of Congo); South America (Brazil, Chile, Guyana and Uruguay).

Climatic experience covers Tropical (high rainfall); Humid Savannah (high seasonal rainfall); Temperate; Semi-arid; Arid; and Hyper Arid.

Do you have a tailings storage facility or potential mine project where you need some help with your tailings storage?

Experience

Zos Uul Gold‐Copper Project

Project Geotechnical Consultant to Western Mongolian Development LLC for their proposed Dry Stacked Tailings Storage Facility (DSTSF) for the Zos Uul Gold‐Copper Project. Tailings testing and evaluation and preparation of a report on that testwork. Future work includes waste (mine waste and tailings storage modelling) stability analysis and preparation of recommendations on dry stacking of tailings.

Country:

Mongolia

Climatic:

Arid

Execution of:

- Routine annual geotechnical reviews of TSF which comprises visual assessment of TSFs, review of operation and management practices and assessment of TSFs in terms of compliance the design and regulatory criteria governing the performance of TSFs.

- Technical reviews of TSF design documents.

- Geotechnical advice on the closure and rehabilitation aspects of TSFs.

Specialising in

Inpit tailings storage facilities

In-pit tailings deposition has grown in popularity for mature mining projects, new projects being developed and potential projects being studied. In-pit tailings storage facilities (IPTSFs) maximise the use of resources and offer many economic and environmental benefits. This technique is not suited to all mining sites.

Integrated waste landforms

The development of new tailings storage facilities (TSF) for mining projects, both new and existing projects, requires innovative design approaches to optimise the available resources and achieve the desired outcomes of safe stable structures with minimal environmental impact.

Dry stacked tailings studies

Dry stacking is the terminology which describes the placement of tailings which has been thickened to a slurry density of 65% – 70% solids by weight, before being filtered/screened to 80% – 90% solids by weight to further reduce the volume of liquor prior to transportation and placement of the tailings.